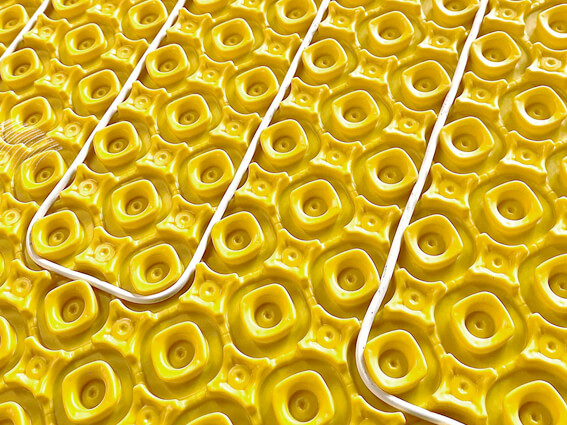

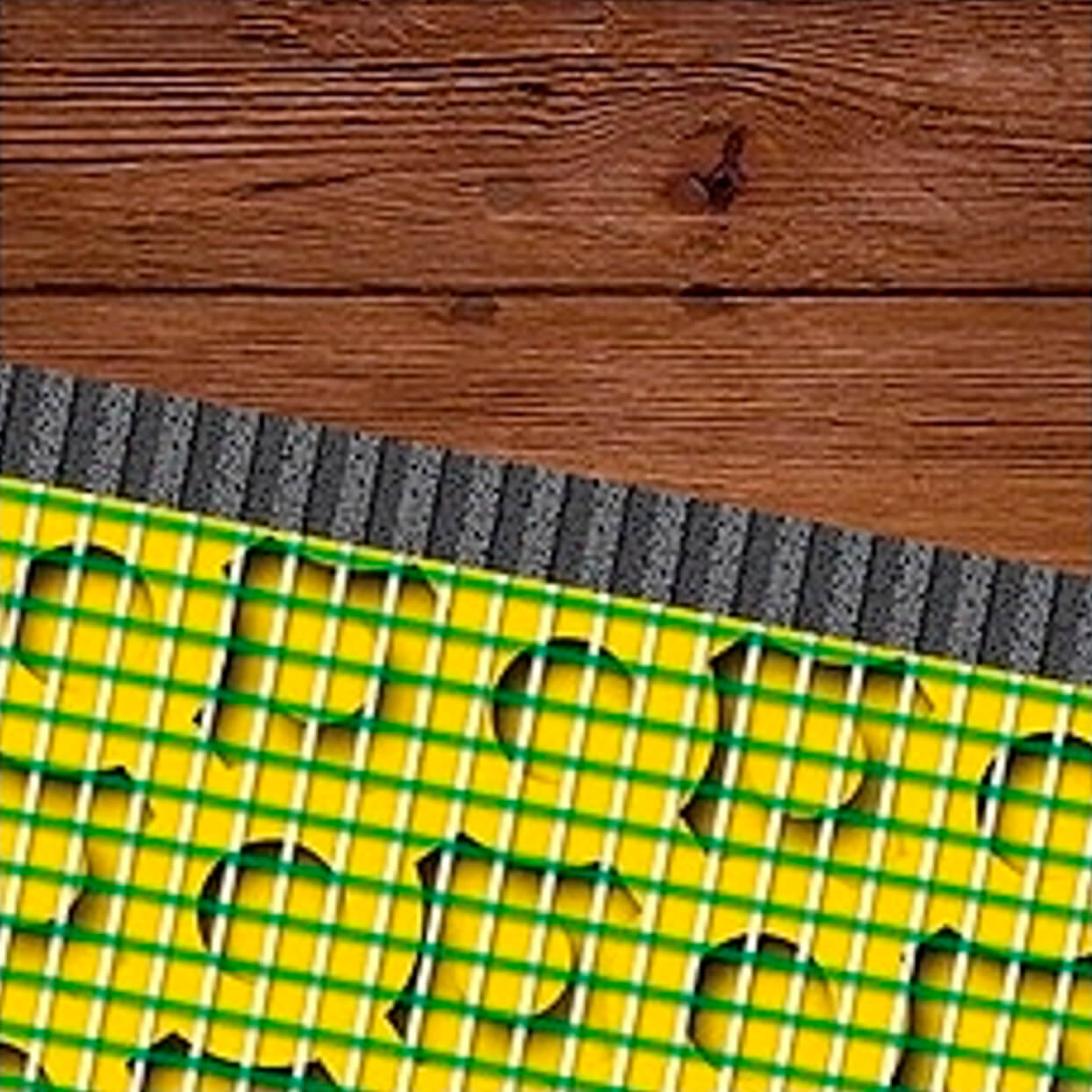

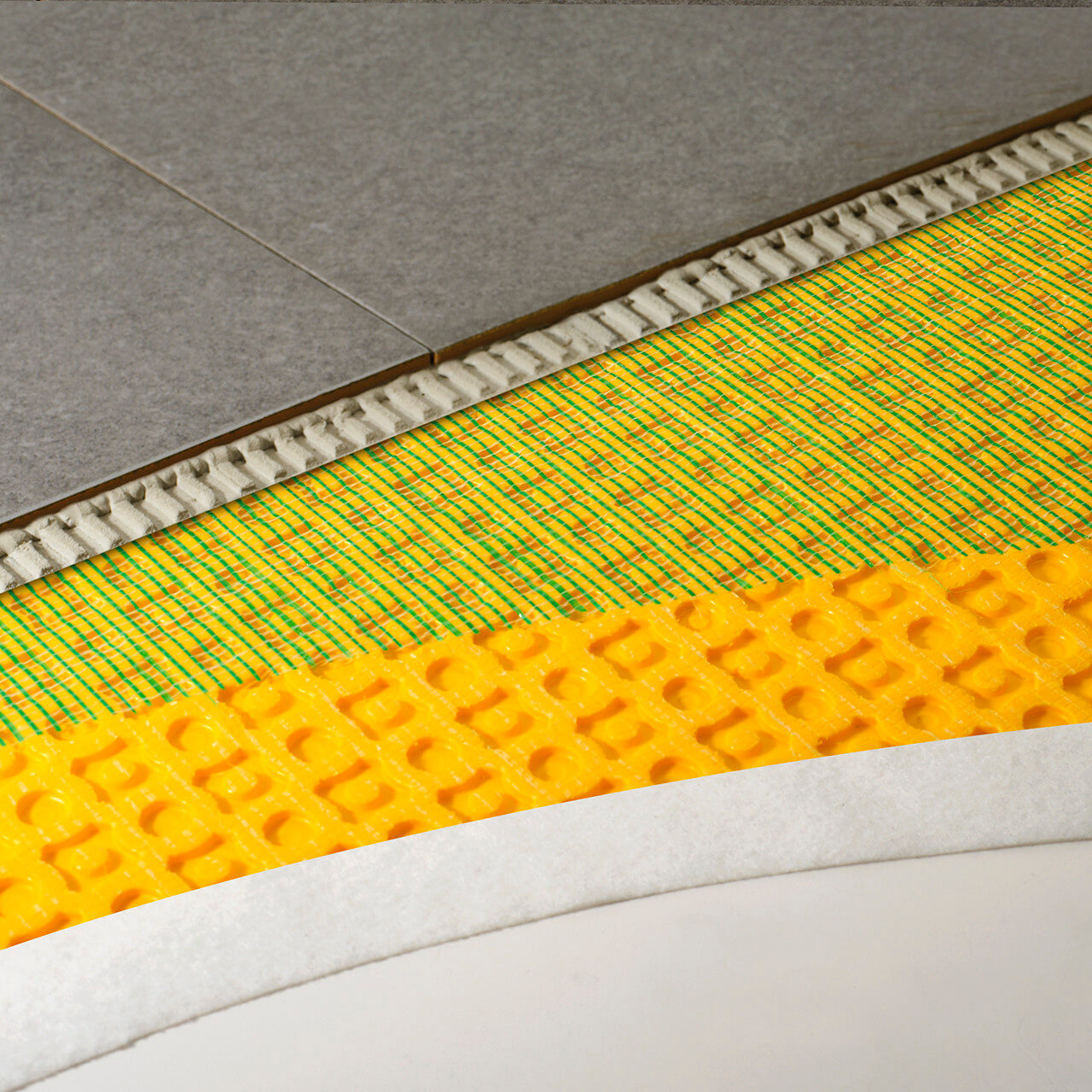

CI+ MATTING

CI+ Matting makes it easier to install floors of all kinds, even on difficult surfaces like old screed or wood, and they also protect the new floor covering from moisture seeping from below as well as preventing stretching or cracks.

VIEW CI+ MATTING